Kia Cadenza YG: Fuel Delivery System / Delivery Pipe Repair procedures

| Removal |

In case of removing the high pressure fuel pump, high

pressure fuel pipe, delivery pipe, and injector, there may be injury

caused by leakage of the high pressure fuel. So don’t do any repair

work right after engine stops.

|

| 1. |

Turn the ignition switch OFF and disconnect the battery negative (-) cable. |

| 2. |

Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - Repair Procedures - "Release Residual Pressure in Fuel Line").

|

| 3. |

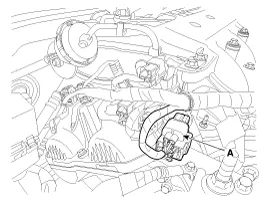

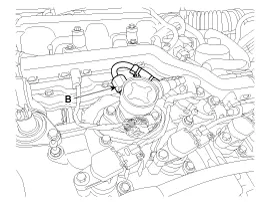

Disconnect the injectors & rail pressure sensor connector (A).

|

| 4. |

Remove the intake manifold.

(Refer to Engine Mechanical System - "Intake Manifold") |

| 5. |

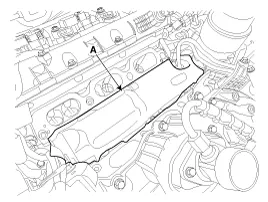

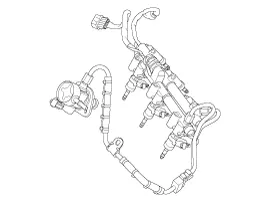

Remove the injector foam (A).

|

| 6. |

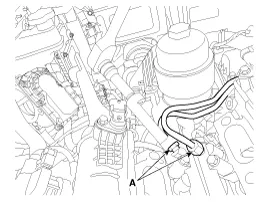

Remove the high pressure fuel pipe.

|

| 7. |

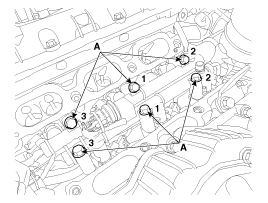

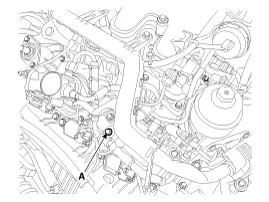

Remove the installation bolt (A), and then remove the delivery pipe and injector assembly from the engine.

|

| Installation |

|

|

|

|

|

|

| 1. |

Install in the reverse order of removal.

|

Removal 1. Turn the ignition switch OFF and disconnect the negative (-) battery cable. 2. Disconnect the accelerator position sensor connector (A).

Removal In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Description and Operation

Description Back view camera will activate when the backup light is ON with the ignition switch ON and the shift lever in the R position. This system is a supplemental system that shows behind the vehicle through the ECM (Reverse Display Room Mirror) mirror or AVN head unit while backing-up.

Kia Cadenza YG 2016-2021 Service Manual: Blower Resistor Repair procedures

Inspection 1. Measure terminal - to - terminal resistance of blower resistor. 2. If measure resistance isnot within specification, the blower resistor must be replaced. Replacement 1. Disconnect the negative (-) battery terminal. 2. Remove the crash pad lower cover (A) and then disconnect the connector (B).

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Schematic Diagrams

- Engine Mechanical System

- Rail Pressure Sensor (RPS) Schematic Diagrams

- New on site

- Most important about car

→

→  →

→  ) in several cycles up to the specified torque.

) in several cycles up to the specified torque.