Kia Cadenza YG: Fuel Delivery System / High Pressure Fuel Pump Repair procedures

| Removal |

In case of removing the high pressure fuel pump, high

pressure fuel pipe, delivery pipe, and injector, there may be injury

caused by leakage of the high pressure fuel. So don’t do any repair

work right after engine stops.

|

| 1. |

Turn the ignition switch OFF and disconnect the battery negative (-) cable. |

| 2. |

Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - Repair Procedures - "Release Residual Pressure in Fuel Line").

|

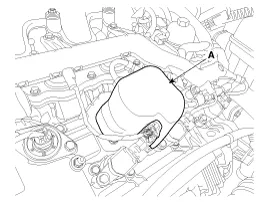

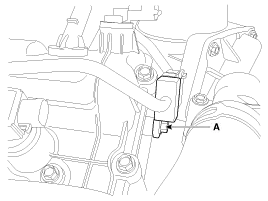

| 3. |

Remove the pump foam (A).

|

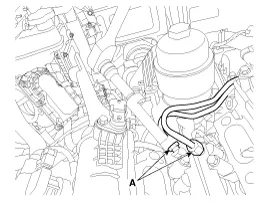

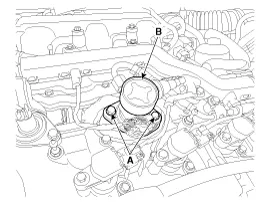

| 4. |

Disconnect the fuel pressure control valve connector (A) and the fuel feed tube quick-connector (B).

|

| 5. |

Remove the intake manifold.

(Refer to Engine Mechanical System - "Intake Manifold") |

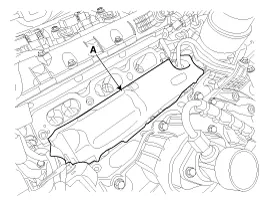

| 6. |

Remove the injector foam (A).

|

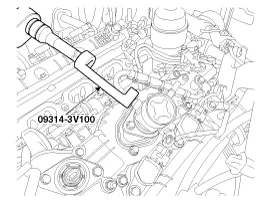

| 7. |

Remove the high pressure fuel pipe.

|

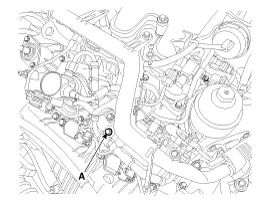

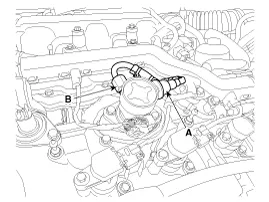

| 8. |

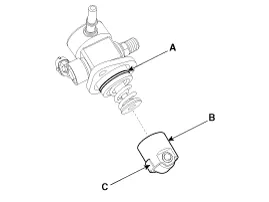

Remove the installation bolts (A), and then remove the high pressure fuel pump (B) from the cylinder head assembly.

|

| Installation |

|

|

|

|

|

|

|

|

| 1. |

Install in the reverse order of removal.

|

Removal In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel.

Removal 1. Lift the vehicle and support the fuel tank with a jack. 2. Remove the nuts from fuel tank. 3. Release the fuel tank bands (A). 4.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Description and Operation

System Overview RPAS (Rear Parking Assist System) is an electronic driving aid that warns the driver to be cautious while parking or in low speed environments. The sensor uses ultrasonic waves to detect objects within proximity of the vehicle.

Kia Cadenza YG 2016-2021 Service Manual: Cluster ionizer Description and Operation

Description 1. The function of cluster ion generator is cleaning air by sterilizing and dissolving of air conditioner. 2. The function of cluster ion generator is controlling mold caused by stench of air conditioner and external inflow of air.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Timing Chain Repair procedures

- Body (Interior and Exterior)

- Automatic Transaxle System

- New on site

- Most important about car