Kia Cadenza YG: Fuel Delivery System / Delivery Pipe Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Engine Control / Fuel System / Fuel Delivery System / Delivery Pipe Repair procedures

| Removal |

In case of removing the high pressure fuel pump, high

pressure fuel pipe, delivery pipe, and injector, there may be injury

caused by leakage of the high pressure fuel. So don’t do any repair

work right after engine stops.

|

| 1. |

Turn the ignition switch OFF and disconnect the battery negative (-) cable. |

| 2. |

Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - Repair Procedures - "Release Residual Pressure in Fuel Line").

|

| 3. |

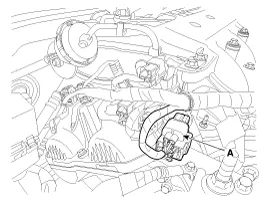

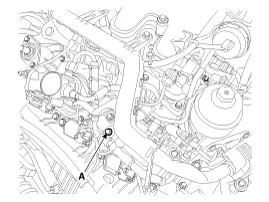

Disconnect the injectors & rail pressure sensor connector (A).

|

| 4. |

Remove the intake manifold.

(Refer to Engine Mechanical System - "Intake Manifold") |

| 5. |

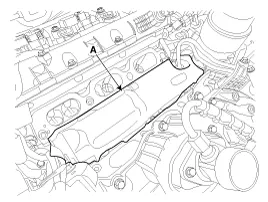

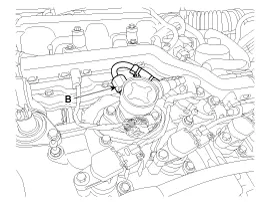

Remove the injector foam (A).

|

| 6. |

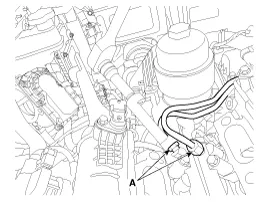

Remove the high pressure fuel pipe.

|

| 7. |

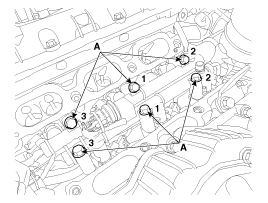

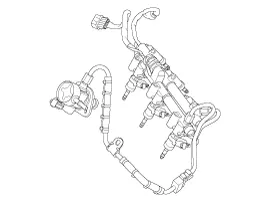

Remove the installation bolt (A), and then remove the delivery pipe and injector assembly from the engine.

|

| Installation |

|

|

|

|

|

|

| 1. |

Install in the reverse order of removal.

|

Removal 1. Turn the ignition switch OFF and disconnect the negative (-) battery cable. 2. Disconnect the accelerator position sensor connector (A).

Removal In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Troubleshooting

Troubleshooting Examples of False-Alarm Occurrence from system characteristics (It’s not a problem) – Characteristics of EM Wave : EM Waves are reflected against all material and especially metal very well. Reflections of EM Waves are varies with the shape of object.

Kia Cadenza YG 2016-2021 Service Manual: Temperature Control Actuator Description and Operation

D

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Timing Chain Repair procedures

- Rail Pressure Sensor (RPS) Schematic Diagrams

- Specifications

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0263

→

→  →

→  ) in several cycles up to the specified torque.

) in several cycles up to the specified torque.