Kia Cadenza YG: Surround View Monitoring (SVM) System / Repair procedures

| Inspection |

| – |

Remove and install a wide camera. |

| – |

Conduct a body task that causes the focus of the wide camera to change, such as a trunk task. |

| – |

Replace the door mirror that has a wide camera. |

| – |

Replace the surround view monitoring unit. |

| 1. |

It shall be prepared as follows.

Apply foot brake or electronic parking brake (EPB) for the vehicle not to move. |

| 2. |

The following procedure shall be performed to check the

normal operation of SVM ECU and camera before entering into the

tolerance calibration mode.

|

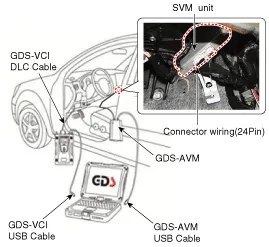

| 3. |

The equipment and vehicle shall be connected as shown in the

following figure in order to perform the SVM manual screen image

calibration.

|

| 4. |

Off the ignition power of the vehicle. |

| 5. |

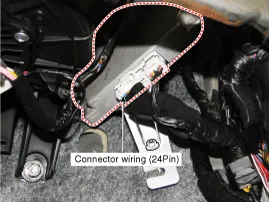

Remove the glove box to couple the connector of the GDS-SVM with SVM unit.

(Refer to Body Electrical System - "Surround View Monitoring Unit") |

| 6. |

Disconnect the connector (24 pin) coupled from SVM unit to wiring harness on the vehicle.

|

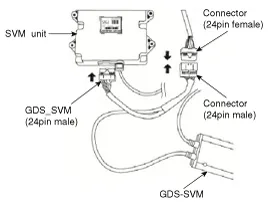

| 7. |

Connect the connector (24 pin) of the GDS-SVM image capture equipment to the point of SVM unit connector.

It is connected in T shape as shown in the following figure.

|

| 8. |

Connect the GDS VCI and vehicle with DLC cable.

|

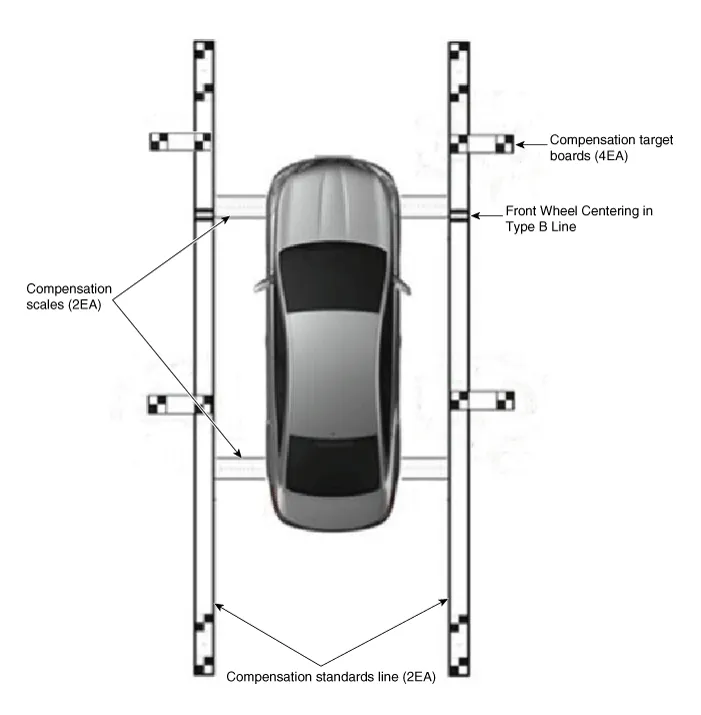

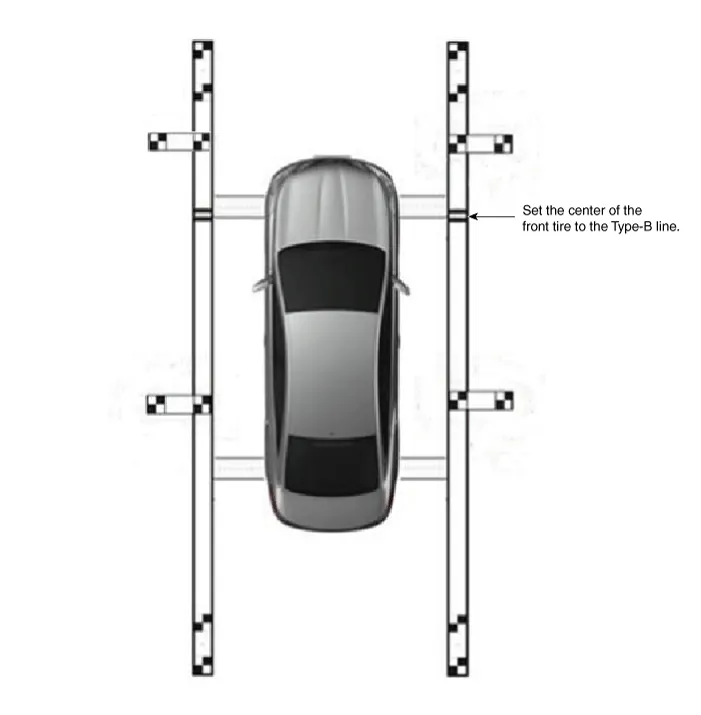

| 9. |

Install the calibration scale (2EA), calibration standard

line board (2EA) and calibration target board (4EA) near to the vehicle

by referring to the enclosed instruction manual.

|

| 10. |

Keep the ignition in ON position at the state of vehicle stop

and check the ''P'' position of gear lever and lock the parking brake

even on the flat ground. |

| 11. |

Perform the work with the SVM switch in the vehicle set to ‘ON.’ |

| 12. |

Perform SVM manual tolerance compensation according to GDS diagnostics display.

|

| 13. |

The next procedure is to proceed by referring to the GDS

screen instructions and the ‘manual tolerance compensation’ manual

supplied along with the equipment.

|

Circuit Diagram SVM System Input/Output 1. Camera input ItemSpecificationLens angle of view190 degreesAngle of viewHorizontal186 degreesVertical135 degreesFunctionProvides the original image of the wide angle image (no additional function)Application locationSame camera applied to the front, rear, left and right 2.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Lane Departure Warning System (LDWS) Unit Repair procedures

Removal 1. Disconnect the negative (-) battery terminal. 2. Remove the LDWS unit cover (A). 3. Remove the LDWS unit connector (A). 4. Remove the LDWS unit after widening the mounting clips. Installation 1. Install the LDWS unit. 2.

Kia Cadenza YG 2016-2021 Service Manual: Troubleshooting

Troubleshooting Examples of False-Alarm Occurrence from system characteristics (It’s not a problem) – Characteristics of EM Wave : EM Waves are reflected against all material and especially metal very well. Reflections of EM Waves are varies with the shape of object.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Engine Electrical System

- Suspension System

- Mode Control Actuator Repair procedures

- New on site

- Most important about car