Kia Cadenza YG: Timing System / Drive Belt Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Engine Mechanical System / Timing System / Drive Belt Repair procedures

| Removal and Installation |

| 1. |

Disconnect the battery negative terminal. |

| 2. |

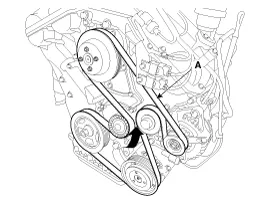

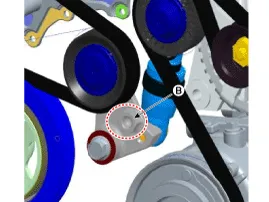

To release the tension, turn the drive belt tensioner counterclockwise then remove the drive belt (A).

|

| 3. |

Installation is reverse order of removal |

| Inspection |

Visually check the belt for excessive wear, frayed cords etc.

If any defect has been found, replace the drive belt.

Cracks on the rib side of a belt are considered acceptable.

If the belt has chunks missing from the ribs, it should be

replaced. |

Components 1. Drive belt

Components 1. Idler

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Specifications

S

Kia Cadenza YG 2016-2021 Service Manual: Ambient Sensor Repair procedures

Inspection 1. Ignition "OFF" 2. Disconnect ambient temperature sensor. 3. Check the resistance of ambient temperature sensor between terminals 1 and 2 whether it is changed by changing of the ambient temperature. 1. Sensor Ground2.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Engine Mechanical System

- Engine Electrical System

- Body Electrical System

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0336