Kia Cadenza YG: Engine Control System / Purge Control Solenoid Valve (PCSV) Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Engine Control / Fuel System / Engine Control System / Purge Control Solenoid Valve (PCSV) Repair procedures

| Inspection |

| 1. |

Turn the ignition switch OFF. |

| 2. |

Disconnect the PCSV connector. |

| 3. |

Measure resistance between the PCSV terminals 1 and 2. |

| 4. |

Check that the resistance is within the specification.

|

| Removal |

| 1. |

Turn the ignition switch OFF and disconnect the battery negative (-) cable. |

| 2. |

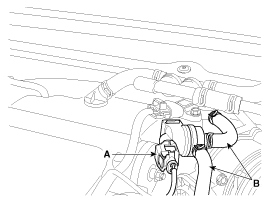

Disconnect the purge control solenoid valve connector (A). |

| 3. |

Disconnect the vapor hoses (B) from the purge control solenoid valve. |

| 4. |

Remove the valve from the bracket.

|

| Installation |

|

|

| 1. |

Install in the reverse order of removal.

|

Circuit Diagram

Description Continuous Variable Valve Timing (CVVT) system advances or retards the valve timing of the intake and exhaust valve in accordance with the ECM control signal which is calculated by the engine speed and load.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Adaptive Front Lighting System Repair procedures

Removal 1. Disconnect the negative (-) battery terminal. 2. Using a screwdriver or remover, remove the crash pad side cover (A). [RH] 3. Disconnect the stopper (B) from the glove box (A). 4. Disconnect the air damper (A) from the glove box (B).

Kia Cadenza YG 2016-2021 Service Manual: Components and Components Location

C

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Schematic Diagrams

- Automatic Transaxle System

- Engine Control / Fuel System

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0206