Kia Cadenza YG: Tires/Wheels / Wheel Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Suspension System / Tires/Wheels / Wheel Repair procedures

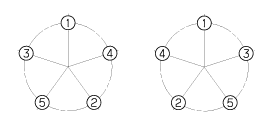

| Hub nut tightening sequence |

Tighten the hub nuts as follows.

Tightening torque:

88.3 ~ 107.9N.m (9.0 ~ 11.0kgf.m, 65.1 ~ 79.6lb-ft) |

When using an impact gun, final tightening torque should be checked using a torque wrench. |

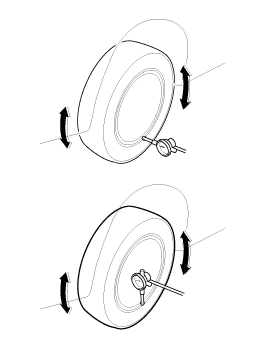

Run out inspection

| 1. |

Jack up the vehicle. |

| 2. |

Measure the wheel Run-out by using a dial indicator as illustration below.

| ||||||||||||

| 3. |

If measured value exceeds the standard value, replace the wheel.

|

Tire wear 1. Measure the tread depth of the tires. Tread depth [limit] : 1.6 mm (0.063 in.) 2. If the remaining tread depth (A) is less than the limit, replace the tire.

Front wheel alignment When using a commercially available computerized wheel alignment equipment to inspect the front wheel alignment, always position the vehicle on a level surface with the front wheels facing straight ahead.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Specifications

S

Kia Cadenza YG 2016-2021 Service Manual: Blind Spot Detection Radar Calibration Description and Operation

Description To sense the cars exactly in the next lane with the radar, the direction of the sensor and the direction of the vehicle have to align. This is BSD unit alignment. If this alignment is not performed as below illustration, the degradation of detection performance and the cause of false alarms.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Emission Control System

- Engine Electrical System

- Engine Mechanical System

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0242