Kia Cadenza YG: Tires/Wheels / Tire Repair procedures

| Tire wear |

| 1. |

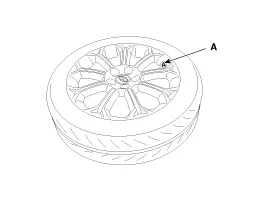

Measure the tread depth of the tires.

|

| 2. |

If the remaining tread depth (A) is less than the limit, replace the tire.

|

| Removal |

| 1. |

Remove the tire. |

| 2. |

Remove the foreign substance from wheel. |

| 3. |

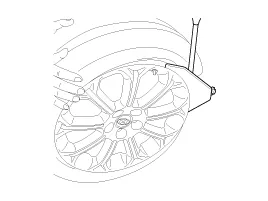

Discharge the air to the tire air inlet (A).

|

| 4. |

Install the bead brake from the tire and then remove the the tire rim by stepping slide bar, a pedal.

|

| 5. |

Carrying out the operation of the brake beads in various places until the fall tire completely from the rim. |

| 6. |

Put on the wheel turn table and then, fixed to the turntable wheel by stepping slide bar, a pedal. |

| 7. |

Install the rim of the wheel head mounting and then fixed.

|

| 8. |

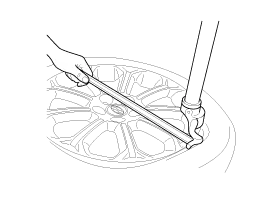

Install the lever and then located to top tire between.

|

| 9. |

By stepping turntable pedal, rotated clockwise the turntable and then separate from the wheel outside the tire. |

| 10. |

Inside of the tire, it is to remove the tire from the wheel in the same way as No. 10.

|

| 11. |

Install in the reverse order of removal. |

Hub nut tightening sequence Tighten the hub nuts as follows. Tightening torque: 88.3 ~ 107.9N.m (9.0 ~ 11.0kgf.m, 65.1 ~ 79.6lb-ft) When using an impact gun, final tightening torque should be checked using a torque wrench.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Schematic Diagrams

C

Kia Cadenza YG 2016-2021 Service Manual: Description and Operation

Description BSD is a system that uses two magnetic wave radar sensors attached on the rear bumper to measure the distance from the following vehicles and provides the sensing and (visual and auditory) alarm of any vehicle coming into the blind spot.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Automatic Transaxle System

- Body Electrical System

- Battery Troubleshooting

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0305