Kia Cadenza YG: Fuel Delivery System / Repair procedures

| Fuel Pressure Test (Low pressure system) |

| 1. |

Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - Repair Procedures - "Release Residual Pressure in Fuel Line").

|

| 2. |

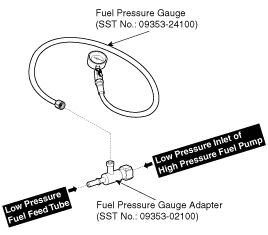

Install the Special Service Tool (SST).

|

| 3. |

Inspect fuel leakage on connections among the low fuel feed

tube, the low pressure inlet of high pressure fuel pump, and the SST

components with IG ON. |

| 4. |

Measure Fuel Pressure.

|

| 5. |

Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - Repair Procedures - "Release Residual Pressure in Fuel Line").

|

| 6. |

Test End

|

| Release Residual Pressure in Fuel Line |

Whenever the high pressure fuel fuse, fuel pipe, delivery

pipe, or injector is removed immediately after shutting off the engine,

an injury may be caused by the release of highly pressurized fuel.

Release the residual pressure in the high pressure fuel line by

referring to the "Residual fuel pressure release procedure" below before

removing any high pressure fuel system components.

|

Wear safety glasses and fuel resistant gloves.

|

| 1. |

Turn the ignition off and disconnect the battery negative cable. |

| 2. |

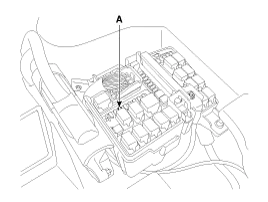

Remove the fuel pump fuse (A).

|

| 3. |

Reconnect the battery negative cable. |

| 4. |

Run the engine for about 1 minutes to lower the pressure in the low pressure line. |

| 5. |

Turn the engine off. |

| 6. |

Disconnect the low pressure fuel line quick connector at the

High Pressure Pump. Use rags to cover opening and catch spills while

removing the fuel line. |

| 7. |

Start the engine and let it idle until the engine stops. At this point the pressure should be under 30 psi. |

| 8. |

Proceed with the service or repair. Use rags to cover opening and catch spills when opening up the high pressure system. |

| 9. |

Reinstall / re-connect all components in reverse order of

removal. Start engine and confirm proper operation, and make sure there

are no fuel leaks. |

| 10. |

After completing, clear DTC(s) using GDS scan tool (the procedure described above will cause DTC to set). |

Components Location [Fuel Tank] 1. Fuel Tank2. Fuel Pump3. Fuel Filter4. Fuel Pressure Regulator5. Canister6. Fuel Tank Air Filter7. Fuel Pressure Sensor (FPS)8.

Removal 1. Release the residual pressure in fuel line. (Refer to the Fuel Delivery System - Repair Procedures - "Release Residual Pressure in Fuel Line").

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Description and Operation

Description Surround View Monitoring System (SVM) is the system that allows video monitoring of 360 degrees around the vehicle. The system includes 4 ultra optical camera mounted around the vehicle (front, both sides, rear). The video from these cameras are applied with distortion compensation, time point conversion, and video merging

Kia Cadenza YG 2016-2021 Service Manual: Description and Operation

System Overview RPAS (Rear Parking Assist System) is an electronic driving aid that warns the driver to be cautious while parking or in low speed environments. The sensor uses ultrasonic waves to detect objects within proximity of the vehicle.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Restraint

- Schematic Diagrams

- Rail Pressure Sensor (RPS) Schematic Diagrams

- New on site

- Most important about car