Kia Cadenza YG: Ignition System / Spark Plug Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Engine Electrical System / Ignition System / Spark Plug Repair procedures

| Inspection |

| [On vehicle inspection] |

| 1. |

Accelerate the engine to about 3,000 rpm 3 times or more. |

| 2. |

Remove the spark plug. |

| 3. |

Check the spark plug visually.

If the electrode is dry, the spark plug is normal.

If the electrode is wet, check the damage and electrode gap as below. |

| [Component Inspection] |

| 1. |

Check the spark plug for any damage on its thread and insulator.

If there is damage, replace the spark plug. |

| 2. |

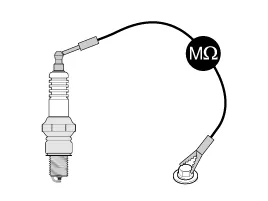

Check the electrode. Measure the insulation resistance with an ohmmeter.

If the resistance is less than the specified value, adjust the electrode gap.

|

| 3. |

Check the spark plug electrode gap.

If the gap is greater than the maximum, replace the spark plug.

|

| Cleaning |

The combustion temporarily becomes unstable, due to the aged

fuel and the carbon deposits accumulated on the spark plug(s) after

long-term storage.

| [1st Method] |

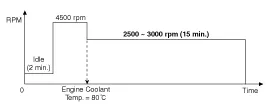

| 1. |

Start the engine and keep the engine running at idle for 2 minutes. |

| 2. |

Step on the accelerator pedal and hold it steady at 4500 rpm

with the shift lever in N position to warm up the engine until the

temperature of the engine coolant reaches 80°C. |

| 3. |

Keep the engine running at 2500~3000 rpm in the N position for 15 minutes.

|

| [2nd Method] |

|

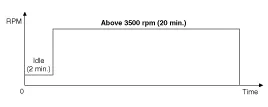

| 1. |

Start the engine and keep the engine running at idle for 2 minutes. |

| 2. |

Drive the vehicle for over 20 minutes, keeping the engine speed above 3500 rpm.

|

| Removal |

| 1. |

Remove the ignition coil.

(Refer to Ignition System - "Ignition Coil") |

| 2. |

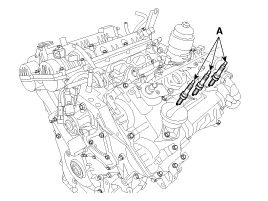

Using a spark plug wrench, remove the spark plug (A).

[Bank1]

[Bank2]

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

Specification ItemSpecificationTypeSILZKR7B11Gap1.0 ~ 1.1 mm (0.0394 ~ 0.0433 in.)

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Components and Components Location

C

Kia Cadenza YG 2016-2021 Service Manual: Specifications

Specification Air Conditioner ItemSpecificationCompressorType6VSX16Oil type & CapacityPAG OIL 100±10Pulley type6PK-TYPEDisplacement160cc/revCondenserHeat rejection14,400 ±5% kcal/hrA/C Pressure transducerThe method to measure the pressureVoltage= 0.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Rail Pressure Sensor (RPS) Schematic Diagrams

- Driveshaft and axle

- General Information

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0187