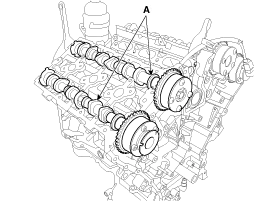

Kia Cadenza YG: Cylinder Head Assembly / Valve Clearance Adjustment

| Valve Clearance Inspection And Adjustment |

Inspect and adjust the valve clearance when the engine is

cold (Engine coolant temperature : 20°C(68°F)) and cylinder head is

installed on the cylinder block. |

| 1. |

Remove the cylinder head cover.

(Refer to Cylinder Head Assembly - "Cylinder Head Cover") |

| 2. |

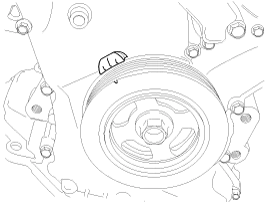

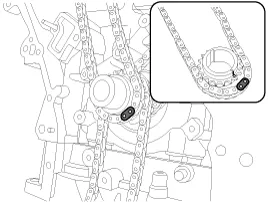

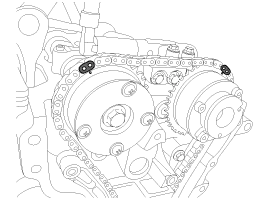

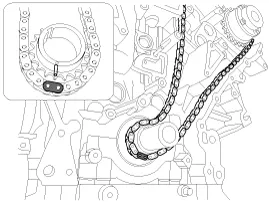

Set No.1 cylinder to TDC/compression.

|

| 3. |

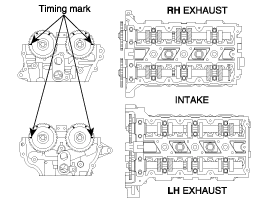

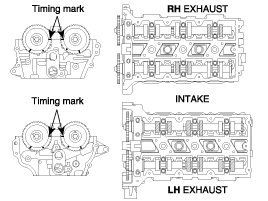

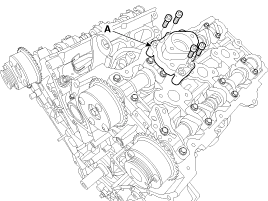

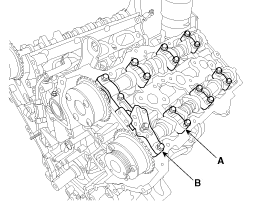

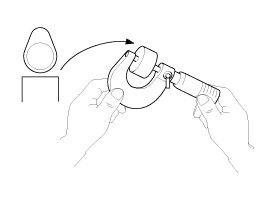

Inspect the valve clearance.

|

| 4. |

Adjust the intake and exhaust valve clearance.

|

Components 1. RH Cylinder head2. RH Cylinder head gasket3. LH Cylinder head4. LH Cylinder head gasket5. Cylinder block 1. Camshaft bearing cap 2.

Removal [LH] 1. Remove the Intake manifold. (Refer to Intake And Exhaust System - "Intake Manifold") 2. Remove the high pressure fuel pump.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Troubleshooting

Troubleshooting Problem Symptoms Table Before replacing or repairing air conditioning components, first determine if the malfunction is due to the refrigerant charge, air flow or compressor. Use the table below to help you find the cause of the problem.

Kia Cadenza YG 2016-2021 Service Manual: Compressor Oil Repair procedures

Oil Specification 1. The HFC-134a system requires synthetic (PAG) compressor oil whereas the R-12 system requires mineral compressor oil. The two oils must never be mixed. 2. Compressor (PAG) oil varies according to compressor model. Be sure to use oil specified for the model of compressor.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Schematic Diagrams

- Restraint

- Body (Interior and Exterior)

- New on site

- Most important about car