Kia Cadenza YG: Automatic Transaxle Control System / 26 Brake Control Solenoid Valve(26/B_VFS) Repair procedures

| Inspection |

| 1. |

Turn ignition switch OFF. |

| 2. |

Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery") |

| 3. |

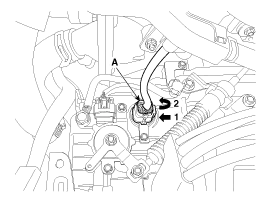

Disconnect the solenoid valve connector (A).

|

| 4. |

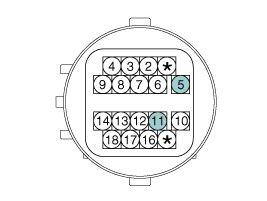

Measure the resistance between power terminal (5) and signal terminal (11).

|

| Replacement |

If a solenoid valve of VFS type needs to be replaced, the

valve body assembly should be replaced and the oil pressure should be

adjusted. If the solenoid valve is replaced individually, it is not

possible to adjust the oil pressure without additional equipment, and if

the oil pressure adjustment procedure is not performed, a shift shock

or delay may occur. |

| 1. |

Replace the valve body assembly.

(Refer to Hydraulic System - "Valve Body") |

Circuit Diagram

Specification Item SpecificationControl typeN/H (Normal High)"Control pressure kpa (kgf/cm², psi)""500.14 ~ 9.81 (5.1 ~ 0.1, 72.54 ~ 1.42)"Current value (mA)50 ~ 850Coil resistance(Ω)5.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Schematic Diagrams

Circuit Diagram SVM System Input/Output 1. Camera input ItemSpecificationLens angle of view190 degreesAngle of viewHorizontal186 degreesVertical135 degreesFunctionProvides the original image of the wide angle image (no additional function)Application locationSame camera applied to the front, rear, left and right 2.

Kia Cadenza YG 2016-2021 Service Manual: Power Mosfet Repair procedures

Inspection 1. Ignition "ON" 2. Manually operate the control switch and measure the voltage of blower motor. 3. Select the control switch to raise voltage until high speed. Specification FanMotor VoltageManualFirst speed3.8 ±0.5VSecond speed5.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Specifications

- Automatic Transaxle System

- Emission Control System

- New on site

- Most important about car