Kia Cadenza YG: Adaptive Front Lighting System / Description and Operation

Kia Cadenza YG 2016-2021 Service Manual / Body Electrical System / Adaptive Front Lighting System / Description and Operation

| Description |

Adaptive Front-lighting System (AFLS)

AFLS(Adaptive Front-lighting System)is a headlamp

orientation control system that takes into account both steering angle

and vehicle speed to orient the headlamps to an angle that provides

better nighttime visibility.

Variable conditions make lighting pattern of running vehicle kaleidoscope.

Component of AFLS

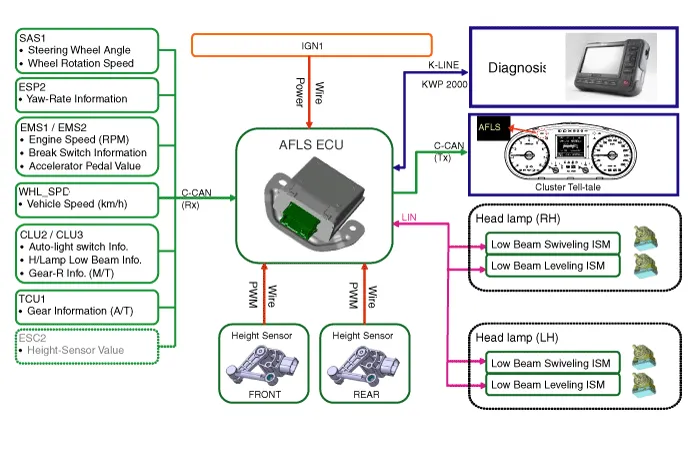

| 1. |

Input part : It is provided that information of speed sensor, height sensor and so on related to condition of vehicle. |

| 2. |

Control part (AFLS Unit) : It controls Output part by analyzing/judging Input signal. |

| 3. |

Output part : It drive Low beam of H/Lamp to upper/lower and

left/right side optimum lighting pattern according to output control

signal of AFLS Unit. |

Main function of AFLS

| Content | Description | |||||||||

| 1 | Dynamic Bending (Swivelling) |

| ||||||||

| 2 | Automatic Leveling (Leveling) |

| ||||||||

| 3 | Fail-safe |

|

Advantage of AFLS

| Content | Description | |||||||

| 1 | Enhanced stability |

| ||||||

| 2 | Enhanced convenience |

|

Block Diagram

| Operation |

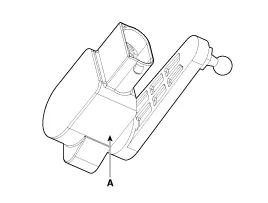

Component

AFLS Unit (A)

| 1. |

General

System initialization, In case of input Engine signal (AFLS ECU, Levelling /Swivelling motor)

Adaptation of AFLS OFF switch

AFLS operate normally ,only under turning auto light switch on.

Providing Tel-tale function of AFLS (display ‘AFLS’ on dashboard).

In case of system failure, display light on ‘AFLS’ on dashboard

|

| 2. |

Main function

Swivelling function

Levelling function

Processing signal of Height sensor

Control the clynamic bending light |

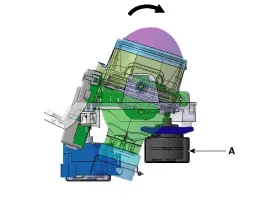

Swivelling Motor (A)

| 1. |

General

communicate AFLS Unit through LIN protocol

Robust control to Disturbance

Doesn''t work out of rated voltage range. |

| 2. |

Main function & Rating

Drive Low beam to left / right side

Fail-safe function : In case of detecting malfunction or system failure , drive to secure position |

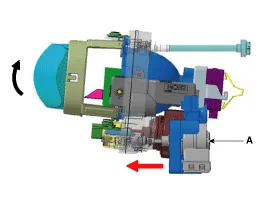

Levelling Motor (A)

| 1. |

Main spec

communicate AFLS Unit through LIN protocol

Robust control to Disturbance

Doesn''t work out of rated voltage range. |

| 2. |

Main function & Rating

Drive Low beam to upper / lower

Fail-safe function : In case of detecting malfunction or system failure , drive to secure position |

Height Sensor

| 1. |

General

Height Sensor connecting body & suspension measures inclination information from load condition.

Vehicle having the Steel-suspension system transmits inclination signal to AFLS ECU by using Hard-wire. |

| 2. |

Rating

Rated Voltage : 5V ± 5% |

Circuit Diagram

Inspection Initialization and diagnosis sequence by using diagnostic equipment Below content summarize the procedure for A/S using Diagnostic equipment Download Parameter 1.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Troubleshooting

Troubleshooting Examples of False-Alarm Occurrence from system characteristics (It’s not a problem) – Characteristics of EM Wave : EM Waves are reflected against all material and especially metal very well. Reflections of EM Waves are varies with the shape of object.

Kia Cadenza YG 2016-2021 Service Manual: A/C Pressure Transducer Repair procedures

Inspection 1. Measure the pressure of high pressure line by measuring voltage output between NO.1 and NO.2 terminals. 2. Inspect the voltage value whether it is sufficient to be regular value or not. Voltage = 0.00878835 * Pressure + 0.37081095 [PSIA] 3.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Alternator Schematic Diagrams

- Transaxle Control Module (TCM) Repair procedures

- Schematic Diagrams

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0194