Kia Cadenza YG: Automatic Transaxle Control System / Transaxle Control Module (TCM) Schematic Diagrams

Kia Cadenza YG 2016-2021 Service Manual / Automatic Transaxle System / Automatic Transaxle Control System / Transaxle Control Module (TCM) Schematic Diagrams

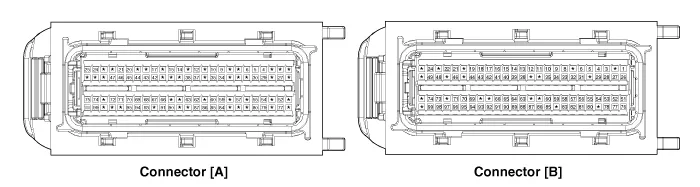

| 1. TCM connector and terminal function |

| 2. TCM terminal function |

Connector [A]

| Pin | Description | Pin | Description |

| 1 | - | 45 | Inhibitor switch signal ''S2'' |

| 2 | - | 46 | Inhibitor switch signal ''S3'' |

| 3 | - | 47 | Inhibitor switch signal ''S4'' |

| 4 | - | 48 | - |

| 5 | - | 49 | - |

| 6 | - | 50 | - |

| 7 | - | 51 | - |

| 8 | - | 52 | - |

| 9 | - | 53 | - |

| 10 | CAN communication line (HIGH) | 54 | Sports mode down switch |

| 11 | - | 55 | - |

| 12 | - | 56 | - |

| 13 | - | 57 | - |

| 14 | - | 58 | - |

| 15 | - | 59 | - |

| 16 | - | 60 | - |

| 17 | - | 61 | - |

| 18 | - | 62 | - |

| 19 | - | 63 | - |

| 20 | - | 64 | - |

| 21 | - | 65 | - |

| 22 | - | 66 | - |

| 23 | - | 67 | - |

| 24 | - | 68 | - |

| 25 | - | 69 | - |

| 26 | - | 70 | - |

| 27 | Ignition switch | 71 | - |

| 28 | - | 72 | - |

| 29 | Sports mode up switch | 73 | - |

| 30 | - | 74 | - |

| 31 | - | 75 | - |

| 32 | - | 76 | - |

| 33 | - | 77 | - |

| 34 | - | 78 | |

| 35 | CAN communication line Low | 79 | Sports mode Select switch |

| 36 | - | 80 | - |

| 37 | - | 81 | - |

| 38 | - | 82 | - |

| 39 | - | 83 | - |

| 40 | - | 84 | Shift lock solenoid |

| 41 | - | 85 | Reverse lamp relay |

| 42 | - | 86 | P/N relay |

| 43 | - | 87 | - |

| 44 | Inhibitor switch signal ''S1'' | 88 | - |

Connector [B]

| Pin | Description | Pin | Description |

| 1 | Overdrive clutch control solenoid valve (VFS) | 52 | Underdrive brake control solenoid valve (VFS) |

| 3 | Input speed sensor signal | 53 | SS-B Solenoid valve (ON/OFF) |

| 4 | Output speed sensor signal | 54 | Output speed sensor power |

| 26 | Torque converter control solenoid valve (VFS) | 55 | Oil temperature sensor (-) |

| 27 | 35R Clutch control solenoid valve (VFS) | 57 | Oil temperature sensor (+) |

| 28 | SS-A Solenoid valve (ON/OFF) | 76 | Solenoid valve power 1 |

| 29 | Input speed sensor power | 77 | Solenoid valve power 2 |

| 51 | Line pressure control solenoid valve (VFS) | 78 | 26 Brake control solenoid valve (VFS) |

| 3. TCM Terminal input/ output signal |

Connector [A]

| Pin No. | Signal | Condition | Type | Level |

| 29 | Sports mode up switch | Up ON | Input | 0V/Battery voltage level |

| Other | 9V < Battery voltage level < 16V | |||

| 44 | Inhibitor switch signal "S1" | ON | Input | 9V < Battery voltage level < 16V |

| OFF | 0V/Battery voltage level | |||

| 45 | Inhibitor switch signal "S2" | ON | Input | 9V < Battery voltage level < 16V |

| OFF | 0V/Battery voltage level | |||

| 46 | Inhibitor switch signal "S3" | ON | Input | 9V < Battery voltage level < 16V |

| OFF | 0V/Battery voltage level | |||

| 47 | Inhibitor switch signal "S4" | ON | Input | 9V < Battery voltage level < 16V |

| OFF | 0V/Battery voltage level | |||

| 54 | Sports mode down switch | Down ON | Input | 0V/Battery voltage level |

| Other | 9V < Battery voltage level < 16V | |||

| 79 | Sports mode select switch | Sport mode | Input | 0V/Battery voltage level |

| Other | 9V < Battery voltage level < 16V | |||

| 84 | Shift lock solenoid | High | Output | 0V/Battery voltage level |

| Low | 9V < Battery voltage level < 16V | |||

| 85 | Rear lamp relay | R ON | Output | 0V/Battery voltage level |

| Other | 9V < Battery voltage level < 16V | |||

| 86 | P/N relay | P-R change | Output | Min. Operation voltage: Battery voltage ≥ 6.0V |

| Max. Operation voltage: Battery voltage ≤ 16.0V | ||||

| P/N range position |

Connector [B]

| Pin No. | Signal | Condition | Type | Level |

| 1 | Overdrive clutch control solenoid valve | | Output | 0V/Battery voltage level |

| 9V < Battery voltage level < 16V | ||||

| Power supply : V_SOL1 | ||||

| 3 | Input speed sensor signal | High | Input | 0.7V/1.4V |

| Low | ||||

| 4 | Output speed sensor signal | High | Input | 0.7V/1.4V |

| Low | ||||

| 26 | Torque converter control solenoid valve | | Output | 0V/Battery voltage level |

| 9V < Battery voltage level < 16V | ||||

| 27 | 35R clutch control solenoid valve | | Output | 0V/Battery voltage level |

| 9V < Battery voltage level < 16V | ||||

| 28 | SS-A Solenoid valve (ON/OFF) | High | Output | 0V/Battery voltage level |

| Low | 9V < Battery voltage level < 16V | |||

| 29 | Input speed sensor power | ON | Power | 0V/7.5V |

| OFF | ||||

| 51 | Line pressure control solenoid valve | | Output | 0V/Battery voltage level |

| 9V < Battery voltage level < 16V | ||||

| 52 | Underdrive brake control solenoid valve | | Output | 0V/Battery voltage level |

| 9V < Battery voltage level < 16V | ||||

| Power supply : V_SOL2 | ||||

| 53 | SS-B Solenoid valve (ON/OFF) | High | Output | 0V/Battery voltage level |

| Low | 9V < Battery voltage level < 16V | |||

| 54 | Output speed sensor power | ON | Power | 0V/7.5V |

| OFF | ||||

| 55 | Oil temperature sensor (-) | | Ground | 0V |

| 76 | Solenoid valve power 1 | ON | Power | 0V/Battery voltage level |

| OFF | 9V < Battery voltage level < 16V | |||

| 77 | Solenoid valve power 1 | ON | Power | 0V/Battery voltage level |

| OFF | 9V < Battery voltage level < 16V | |||

| 78 | 26 brake control solenoid valve | | Output | 0V/Battery voltage level |

| 9V < Battery voltage level < 16V | ||||

| Power supply : V_SOL2 |

Description Transaxle Control Module (TCM) is the automatic transaxle''s brain. The module receives and processes signals from various sensors and implements a wide range of transaxle controls to ensure optimal driving conditions for the driver.

Removal When replacing the TCM, the vehicle equipped with the immobilizer must be performed procedure as below. [In the case of installing used TCM] 1) Perform "TCM Neutral mode" procedure with GDS.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Mode Control Actuator Repair procedures

- Driveshaft and axle

- General Information

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.027