Kia Cadenza YG: Lubrication System / Oil Pressure Switch Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Engine Mechanical System / Lubrication System / Oil Pressure Switch Repair procedures

| Removal and Installaion |

| 1. |

Remove the intake manifold.

(Refer to Intake And Exhaust System - "Intake Manifold") |

| 2. |

Remove the delivery pipe and injector.

(Refer to Engine Control / Fuel System - "Delivery Pipe") |

| 3. |

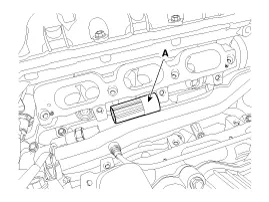

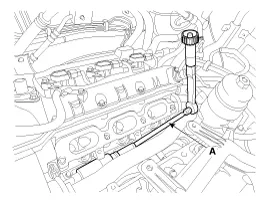

Remove the oil pressure switch (A) after disconnecting the connector.

|

| 4. |

Install in the reverse order of removal.

|

| Inspection |

| 1. |

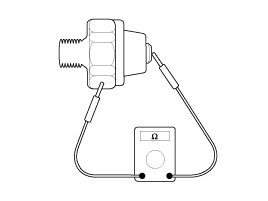

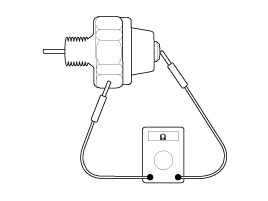

Check the continuity between the terminal and the body with an ohmmeter.

If there is no continuity, replace the oil pressure switch.

|

| 2. |

Check the continuity between the terminal and the body when

the fine wire is pushed. If there is continuity even when the fine wire

is pushed, replace the switch.

|

| 3. |

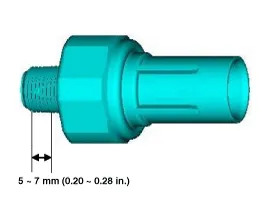

If there is no continuity when a 50 kpa (7psi) is applied

through the oil hole the switch is operaing properly. Check for air

leakage. If air leaks, the diaphragm is broken. Replace it. |

Components 1. Oil cover2. Oil cover gasket3. Oil pressure switch

Components 1. Oil level gauge2. Oil level gauge pipe3. O-ring

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Description and Operation

System Overview RPAS (Rear Parking Assist System) is an electronic driving aid that warns the driver to be cautious while parking or in low speed environments. The sensor uses ultrasonic waves to detect objects within proximity of the vehicle.

Kia Cadenza YG 2016-2021 Service Manual: A/C Pressure Transducer Description and Operation

Description A/C pressure transducer convert the pressure value of high pressure line into voltage value after measure it. By converted voltage value, engine ECU controls cooling fan by operating it high speed or low speed. Engine ECU stop the operation of compressor when the temperature of refrigerant line is so high or so low irregularl

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Driveshaft and axle

- Engine Control / Fuel System

- Components and Components Location

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0258

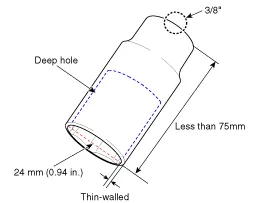

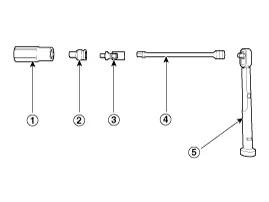

24mm deep socket

24mm deep socket 1/2" to 3/8" drive socket adapter (only if using 1/2" drive deep socket)

1/2" to 3/8" drive socket adapter (only if using 1/2" drive deep socket) 3/8" universal joint

3/8" universal joint 3/8" extension bar

3/8" extension bar Socket wrench

Socket wrench