Kia Cadenza YG: Fuses And Relays / Relay Box (Engine Compartment) Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Body Electrical System / Fuses And Relays / Relay Box (Engine Compartment) Repair procedures

| Inspection |

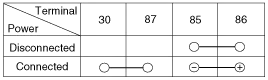

Power Relay Test (Type A)

|

Check for continuity between the terminals.

| A. Front deicer B. IGN2 relay C. Blower relay D. Burglar alarm horn relay E. IGN1 relay F. Cooling fan #1 relay | G. Cooling fan #2 relay H. Start relay I. Rear defogger J. Horn relay K. ACC relay L. Fuel pump relay |

| 1. |

There should be continuity between the No.30 and No.87

terminals when power and ground are connected to the No.85 and No.86

terminals. |

| 2. |

There should be no continuity between the No.30 and No.87 terminals when power is disconnected.

|

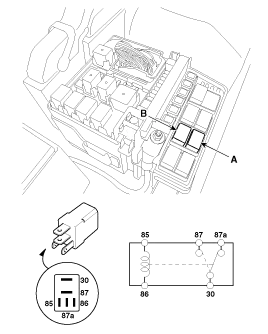

Power Relay Test (Type B)

Check for continuity between the terminals.

A : Rain sensor relay

B : Wiper relay

| 1. |

There should be continuity between the No.30 and No.87

terminals when power and ground are connected to the No.85 and No.86

terminals. |

| 2. |

There should be continuity between the No.30 and No.87 terminals when power is disconnected.

|

Power Relay Test (Type C)

Check for continuity between the terminals.

A : ECU relay

| 1. |

There should be continuity between the No.30, 87a and No.87

terminals when power and ground are connected to the No.85 and No.86

terminals. |

| 2. |

There should be no continuity between the No.30, 87a and No.87 terminals when power is disconnected.

|

Fuse Inspection

| 1. |

Be sure there is no play in the fuse holders, and that the fuses are held securely. |

| 2. |

Are the fuse capacities for each circuit correct? |

| 3. |

Are there any blown fuses?

If a fuse is to be replaced, be sure to use a new fuse of the

same capacity. Always determine why the fuse blew first and completely

eliminate the problem before installing a new fuse. |

Multi Fuse

Multi Fuse is for optimizing the engine room package.

|

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Ambient Sensor Description and Operation

Description 1. The ambient temperature sensor is located at the front of the condenser and detects ambient air temperature. It is a negative type thermistor resistance will increase with lower temperature, and decrease with higher temperatures.

Kia Cadenza YG 2016-2021 Service Manual: Auto defoging sensor Repair procedures

Inspection 1. Press the OFF switch more then 4 times within 2 seconds while pressing the MODE switch. DisplayFail description00Normal23Auto defog sensor OPEN24Auto defog sensor SHORT43Defog door potentiometer OPEN/SHORT44Defog door potentiometer * Diagnostic procedure refer to DTC code.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- General Information

- Restraint

- Front Bumper Repair procedures

- New on site

- Most important about car

Copyright © 2025 www.kcadenzavg.com - 0.0208