Kia Cadenza YG: Engine Control System / Engine Control Module (ECM) Repair procedures

| Removal |

When replacing the ECM, the vehicle equipped with the immobilizer must be performed procedure as below.

[In the case of installing used ECM]

[In the case of installing new ECM]

Perform "Key teaching" procedure with GDS.

(Refer to Body Electrical System - "Immobilizer System")

|

When replacing the ECM, the vehicle equipped with the smart key system (Button start) must be performed procedure as below.

[In the case of installing used ECM]

[In the case of installing new ECM]

Insert the key (or press the start button) and turn it to the

IGN ON and OFF position. Then the ECM learns the smart key information

automatically.

|

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable. |

| 2. |

Remove the cover. |

| 3. |

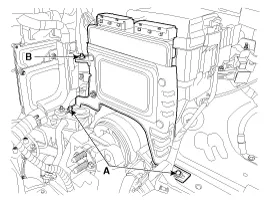

Disconnect the ECM connector (A).

|

| 4. |

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air cleaner" ) |

| 5. |

Remove the battery tray.

(Refer to Engine Electrical System - "Battery") |

| 6. |

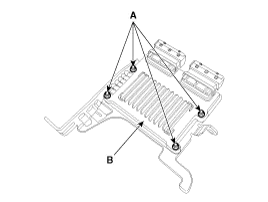

Remove the ECM bracket installation bolts (A) and nut (B).

|

| 7. |

After removing the installation nuts (A), remove the ECM (B) from the bracket.

|

| Installation |

When replacing the ECM, the vehicle equipped with the immobilizer must be performed procedure as below.

[In the case of installing used ECM]

[In the case of installing new ECM]

Perform "Key teaching" procedure with GDS.

(Refer to Body Electrical System - "Immobilizer System")

|

When replacing the ECM, the vehicle equipped with the smart key system (Button start) must be performed procedure as below.

[In the case of installing used ECM]

[In the case of installing new ECM]

Insert the key (or press the start button) and turn it to the

IGN ON and OFF position. Then the ECM learns the smart key information

automatically.

|

| 1. |

Install in the reverse order of removal.

|

| ECM Problem Inspection Procedure |

| 1. |

TEST ECM GROUND CIRCUIT: Measure resistance between ECM and

chassis ground using the backside of ECM harness connector as ECM side

check point. If the problem is found, repair it.

|

| 2. |

TEST ECM CONNECTOR: Disconnect the ECM connector and visually

check the ground terminals on ECM side and harness side for bent pins

or poor contact pressure. If the problem is found, repair it. |

| 3. |

If problem is not found in Step 1 and 2, the ECM could be

faulty. If so, replace the ECM with a new one, and then check the

vehicle again. If the vehicle operates normally then the problem was

likely with the ECM. |

| 4. |

RE-TEST THE ORIGINAL ECM: Install the original ECM (may be

broken) into a known-good vehicle and check the vehicle. If the problem

occurs again, replace the original ECM with a new one. If problem does

not occur, this is intermittent problem.

(Refer to “Intermittent Problem Inspection Procedure” in Basic Inspection Procedure)

|

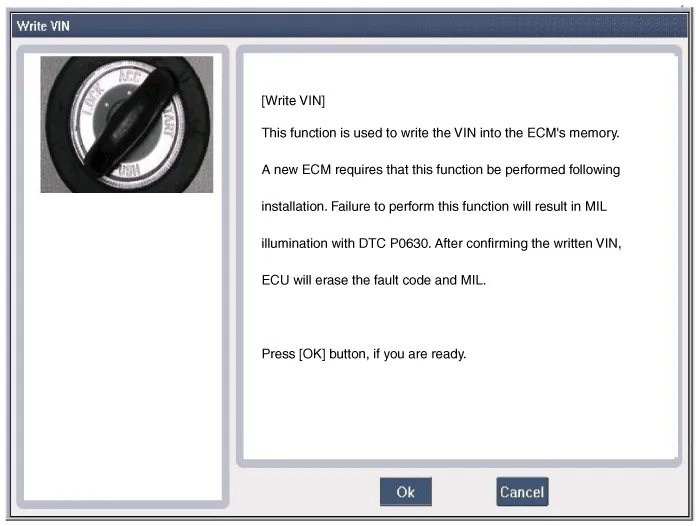

The programmed VIN cannot be changed. When writing the VIN, confirm the VIN carefully |

| 1. |

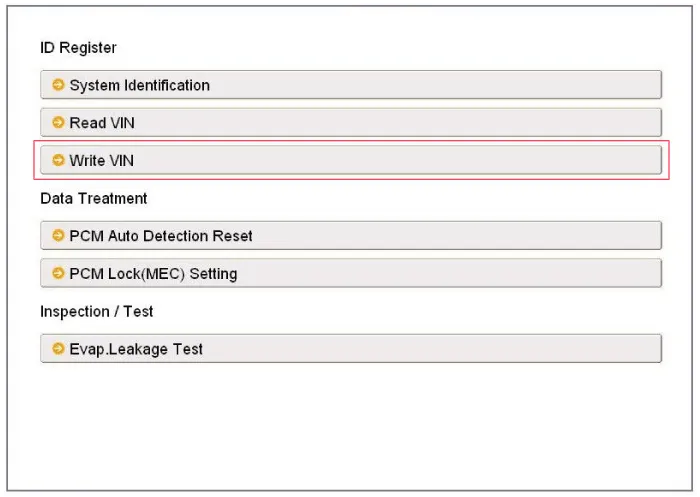

Select "VIN Writing" function in "Vehicle S/W Management". |

| 2. |

Select "Write VIN" in "ID Register".

|

| 3. |

Input the VIN.

|

| 4. |

Turn the ignition switch OFF, then back ON. |

ECM Terminal And Input/Output signal ECM Terminal Function Connector [E600-A] Pin No.DescriptionConnected to1- 2- 3- 4Immobilizer Lamp control outputImmobilizer Lamp [Without Button Engine Start System]5Power groundChassis Ground6Power groundChassis Ground7- 8- 92nd CAN [High]Multi-Purpose Check Connector10CAN [High]Other control module, Data Link Connector (DLC), Multi-Purpose Check Connector11Fuel Tank Pressure Sensor (FTPS) signal inputFuel Tank Pressure Sensor (FTPS)12Electrical Load signal inputHead Lamp Relay13- 14Sensor power (+5V)Accelerator Position Sensor (APS) 115Sensor power (+5V)A/C Pressure Transducer (APT)Rail Pressure Sensor (RPS)16Fuel Level Sender (FLS) signal inputFuel Level Sender (FLS)17-18- 19- 20A/C Compressor relay signal outputA/C Control Module21Brake Switch 2 signal inputBrake Switch22- 23- 24Alternator PWM signal input [FR]Alternator25-26- 27Battery power (B+)Ignition Switch28Rail Pressure Sensor (RPS) signal inputRail Pressure Sensor (RPS)29- 30Power groundChassis Ground31- 32- 33- 342nd CAN [Low]Multi-Purpose Check Connector35CAN [Low]Other control module, Data Link Connector (DLC), Multi-Purpose Check Connector36- 37Sensor groundRail Pressure Sensor (RPS)38Accelerator Position Sensor (APS) 1 signal inputAccelerator Position Sensor (APS) 139- 40- 41-42A/C Switch "ON" signal inputA/C Control Module43Brake Switch 1 signal inputBrake Switch44- 45- 46- 47- 48-49- 50- 51- 52Battery power (B+)Battery53- 54- 55Power groundChassis Ground56- 57A/C Compressor Clutch Relay control outputA/C Control Module [With Immobilzer]58- 59Sensor groundAccelerator Position Sensor (APS) 260Sensor groundAccelerator Position Sensor (APS) 161Sensor groundFuel Tank Pressure Sensor (FTPS)62GroundCruise Control Switch63Sensor groundA/C Pressure Transducer (APT)64- 65Sensor Power (+5V)Fuel Tank Pressure Sensor (FTPS)66Cruise Control Switch signal inputCruise Control Switch67A/C Pressure Transducer (APT) signal inputA/C Pressure Transducer (APT)68Accelerator Position Sensor (APS) 2 signal inputAccelerator Position Sensor (APS) 269-70Engine speed signal outputPower Distribution Module (PDM)71Cooling Fan Relay [High] control outputCooling Fan Relay [High]72Alternator PWM signal output (COM)Alternator73- 74Immobilizer communication lineSmart Key Control Module [With Button Engine Start System]Immobilizer Control Unit [Without Button Engine Start System]75Battery power (B+)Main Relay76- 77Battery power (B+)Battery78-79- 80Power groundChassis ground81- 82- 83- 84- 85- 86- 87LIN (Local Interconnect Network) Serial Bus LineBattery Sensor88- 89- 90Sensor power (+5V)Accelerator Position Sensor (APS) 291Cooling Fan Relay [Low] control outputCooling Fan Relay [Low]92- 93Starter Relay control outputStarter Relay94Main Relay control outputMain Relay95Fuel pump Relay control outputFuel pump Relay 96Canister Close Valve (CCV) control outputCanister Close Valve (CCV)97- 98- 99Battery power (B+)Main Relay100Battery power (B+)Main Relay Connector [C600-B] Pin No.

IDB terminal and Inoutput IDB terminal function Connector [C602] Pin No.DescriptionConnected to1- 2- 3- 4- 5- 6- 7- 8- 9- 10- 11- 12- 13- 14- 15- 16Injector (Cylinder #3) [Low] control outputInjector (Cylinder #3)17Injector (Cylinder #6) [Low] control outputInjector (Cylinder #6)18Injector (Cylinder #6) [High] control outputInjector (Cylinder #6)19Injector (Cylinder #2) [Low] control outputInjector (Cylinder #2)20Injector (Cylinder #5) [Low] control outputInjector (Cylinder #5)21- 22Injector (Cylinder #2) signal inputEngine Control Module (ECM)23Injector (Cylinder #5) signal inputEngine Control Module (ECM)24- 25Fuel Pressure Control Valve (FPRV) logic inputEngine Control Module (ECM)26CCP-CAN [Low]Other control module, Data Link Connector (DLC), Multi-purpose check connector27CCP-CAN [High]Other control module, Data Link Connector (DLC), Multi-purpose check connector28Battery power (B+)Ignition switch29Battery power (B+)Main relay30Battery power (B+)Main relay31Injector (Cylinder #4) [High] control outputInjector (Cylinder #4)32Injector (Cylinder #1) [High] control outputInjector (Cylinder #1)33Injector (Cylinder #3) [High] control outputInjector (Cylinder #3)34Injector (Cylinder #2) [High] control outputInjector (Cylinder #2)35Injector (Cylinder #5) [High] control outputInjector (Cylinder #5)36- 37- 38Injector (Cylinder #3) signal inputEngine Control Module (ECM)39- 40Injector (Cylinder #6) signal inputEngine Control Module (ECM)41Injector (Cylinder #4) signal inputEngine Control Module (ECM)42Battery power (B+)Ignition switch43Battery power (B+)Main relay44Battery power (B+)Main relay45Fuel Pressure Control Valve (FPRV) [High] control outputFuel Pressure Control Valve (FPRV)46Injector (Cylinder #4) [Low] control outputInjector (Cylinder #4)47Injector (Cylinder #1) [Low] control outputInjector (Cylinder #1)48ECM groundChassis ground49ECM groundChassis ground50ECM groundChassis ground51- 52ECM groundChassis ground53ECM groundChassis ground54- 55Injector (Cylinder #1) signal inputEngine Control Module (ECM)56- 57- 58- 59Battery power (B+)Main relay60Fuel Pressure Control Valve (FPRV) [Low] control outputFuel Pressure Control Valve (FPRV) IDB Terminal input/output signal Connector [C602] Pin No.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Pantoscopic Camera Components and Components Location

C

Kia Cadenza YG 2016-2021 Service Manual: Blower Motor Repair procedures

Inspection 1. Connect the battery voltage and check the blower motor rotation. 2. If the blower motor voltage is not operated well, substitute with a known-good blower motor and check for proper operation. 3. If the problem is corrected, replace the blower motor.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Brake System

- Alternator Schematic Diagrams

- Front Bumper Repair procedures

- New on site

- Most important about car