Kia Cadenza YG: Engine Control System / Injector Drive Box (IDB) Schematic Diagrams

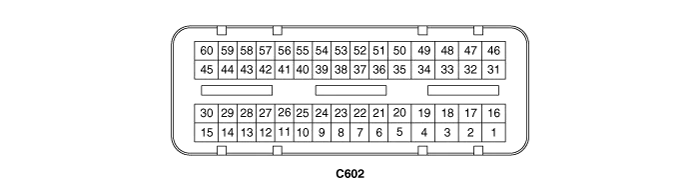

| IDB terminal and Inoutput |

| IDB terminal function |

| Pin No. | Description | Connected to |

| 1 | - | |

| 2 | - | |

| 3 | - | |

| 4 | - | |

| 5 | - | |

| 6 | - | |

| 7 | - | |

| 8 | - | |

| 9 | - | |

| 10 | - | |

| 11 | - | |

| 12 | - | |

| 13 | - | |

| 14 | - | |

| 15 | - | |

| 16 | Injector (Cylinder #3) [Low] control output | Injector (Cylinder #3) |

| 17 | Injector (Cylinder #6) [Low] control output | Injector (Cylinder #6) |

| 18 | Injector (Cylinder #6) [High] control output | Injector (Cylinder #6) |

| 19 | Injector (Cylinder #2) [Low] control output | Injector (Cylinder #2) |

| 20 | Injector (Cylinder #5) [Low] control output | Injector (Cylinder #5) |

| 21 | - | |

| 22 | Injector (Cylinder #2) signal input | Engine Control Module (ECM) |

| 23 | Injector (Cylinder #5) signal input | Engine Control Module (ECM) |

| 24 | - | |

| 25 | Fuel Pressure Control Valve (FPRV) logic input | Engine Control Module (ECM) |

| 26 | CCP-CAN [Low] | Other control module, Data Link Connector (DLC), Multi-purpose check connector |

| 27 | CCP-CAN [High] | Other control module, Data Link Connector (DLC), Multi-purpose check connector |

| 28 | Battery power (B+) | Ignition switch |

| 29 | Battery power (B+) | Main relay |

| 30 | Battery power (B+) | Main relay |

| 31 | Injector (Cylinder #4) [High] control output | Injector (Cylinder #4) |

| 32 | Injector (Cylinder #1) [High] control output | Injector (Cylinder #1) |

| 33 | Injector (Cylinder #3) [High] control output | Injector (Cylinder #3) |

| 34 | Injector (Cylinder #2) [High] control output | Injector (Cylinder #2) |

| 35 | Injector (Cylinder #5) [High] control output | Injector (Cylinder #5) |

| 36 | - | |

| 37 | - | |

| 38 | Injector (Cylinder #3) signal input | Engine Control Module (ECM) |

| 39 | - | |

| 40 | Injector (Cylinder #6) signal input | Engine Control Module (ECM) |

| 41 | Injector (Cylinder #4) signal input | Engine Control Module (ECM) |

| 42 | Battery power (B+) | Ignition switch |

| 43 | Battery power (B+) | Main relay |

| 44 | Battery power (B+) | Main relay |

| 45 | Fuel Pressure Control Valve (FPRV) [High] control output | Fuel Pressure Control Valve (FPRV) |

| 46 | Injector (Cylinder #4) [Low] control output | Injector (Cylinder #4) |

| 47 | Injector (Cylinder #1) [Low] control output | Injector (Cylinder #1) |

| 48 | ECM ground | Chassis ground |

| 49 | ECM ground | Chassis ground |

| 50 | ECM ground | Chassis ground |

| 51 | - | |

| 52 | ECM ground | Chassis ground |

| 53 | ECM ground | Chassis ground |

| 54 | - | |

| 55 | Injector (Cylinder #1) signal input | Engine Control Module (ECM) |

| 56 | - | |

| 57 | - | |

| 58 | - | |

| 59 | Battery power (B+) | Main relay |

| 60 | Fuel Pressure Control Valve (FPRV) [Low] control output | Fuel Pressure Control Valve (FPRV) |

| IDB Terminal input/output signal |

| Pin No. | Description | Condition | Type | Level |

| 1 | - | | | |

| 2 | - | | | |

| 3 | - | | | |

| 4 | - | | | |

| 5 | - | | | |

| 6 | - | | | |

| 7 | - | | | |

| 8 | - | | | |

| 9 | - | | | |

| 10 | - | | | |

| 11 | - | | | |

| 12 | - | | | |

| 13 | - | | | |

| 14 | - | | | |

| 15 | - | | | |

| 16 | Injector (Cylinder #3) [Low] control output | Idle | Pulse | High: Battery voltage |

| Relay ON | Low: Max. 1.0V | |||

| 17 | Injector (Cylinder #6) [Low] control output | Idle | Pulse | High: Battery voltage |

| Relay ON | Low: Max. 1.0V | |||

| 18 | Injector (Cylinder #6) [High] control output | Idle | Pulse | High: Battery voltage ~ 80V |

| Relay ON | Low: Battery voltage | |||

| 19 | Injector (Cylinder #2) [Low] control output | Idle | Pulse | High: Battery voltage |

| Relay ON | Low: Max. 1.0V | |||

| 20 | Injector (Cylinder #5) [Low] control output | Idle | Pulse | High: Battery voltage |

| Relay ON | Low: Max. 1.0V | |||

| 21 | - | | | |

| 22 | Injector (Cylinder #2) signal input | Idle | Pulse | High: Battery voltage |

| Low: Max. 1.0V | ||||

| 23 | Injector (Cylinder #5) signal input | Idle | Pulse | High: Battery voltage |

| Low: Max. 1.0V | ||||

| 24 | - | | | |

| 25 | Fuel Pressure Control Valve (FPRV) logic input | | | |

| | | | ||

| 26 | CCP-CAN [Low] | Recessive | Pulse | 2.0 ~ 3.0V |

| Dominant | 2.75 ~ 4.5V | |||

| 27 | CCP-CAN [High] | Recessive | Pulse | 2.0 ~ 3.0V |

| Dominant | 2.75 ~ 4.5V | |||

| 28 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 29 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 30 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 31 | Injector (Cylinder #4) [High] control output | Idle | Pulse | High: Battery voltage ~ 80V |

| Relay ON | Low: Battery voltage | |||

| 32 | Injector (Cylinder #1) [High] control output | Idle | Pulse | High: Battery voltage ~ 80V |

| Relay ON | Low: Battery voltage | |||

| 33 | Injector (Cylinder #3) [High] control output | Idle | Pulse | High: Battery voltage ~ 80V |

| Relay ON | Low: Battery voltage | |||

| 34 | Injector (Cylinder #2) [High] control output | Idle | Pulse | High: Battery voltage ~ 80V |

| Relay ON | Low: Battery voltage | |||

| 35 | Injector (Cylinder #5) [High] control output | Idle | Pulse | High: Battery voltage ~ 80V |

| Relay ON | Low: Battery voltage | |||

| 36 | - | | | |

| 37 | - | | | |

| 38 | Injector (Cylinder #3) signal input | Idle | Pulse | High: Battery voltage |

| Low: Max. 1.0V | ||||

| 39 | - | | | |

| 40 | Injector (Cylinder #6) signal input | Idle | Pulse | High: Battery voltage |

| Low: Max. 1.0V | ||||

| 41 | Injector (Cylinder #4) signal input | Idle | Pulse | High: Battery voltage |

| Low: Max. 1.0V | ||||

| 42 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 43 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 44 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 45 | Fuel Pressure Control Valve (FPRV) [High] control output | Idle | DC voltage | Battery voltage |

| Max. 1.0V | ||||

| 46 | Injector (Cylinder #4) [Low] control output | Idle | Pulse | High: Battery voltage |

| Relay ON | Low: Max. 1.0V | |||

| 47 | Injector (Cylinder #1) [Low] control output | Idle | Pulse | High: Battery voltage |

| Relay ON | Low: Max. 1.0V | |||

| 48 | ECM ground | Idle | DC voltage | Max. 50mV |

| 49 | ECM ground | Idle | DC voltage | Max. 50mV |

| 50 | ECM ground | Idle | DC voltage | Max. 50mV |

| 51 | - | | | |

| 52 | ECM ground | Idle | DC voltage | Max. 50mV |

| 53 | ECM ground | Idle | DC voltage | Max. 50mV |

| 54 | - | | | |

| 55 | Injector (Cylinder #1) signal input | Idle | Pulse | High: Battery voltage |

| Low: Max. 1.0V | ||||

| 56 | - | | | |

| 57 | - | | | |

| 58 | - | | | |

| 59 | Battery power (B+) | IG OFF | DC voltage | Max. 0.5V |

| IG ON | Battery voltage | |||

| 60 | Fuel Pressure Control Valve (FPRV) [Low] control output | Idle | DC voltage | Battery voltage |

| Max. 1.0V |

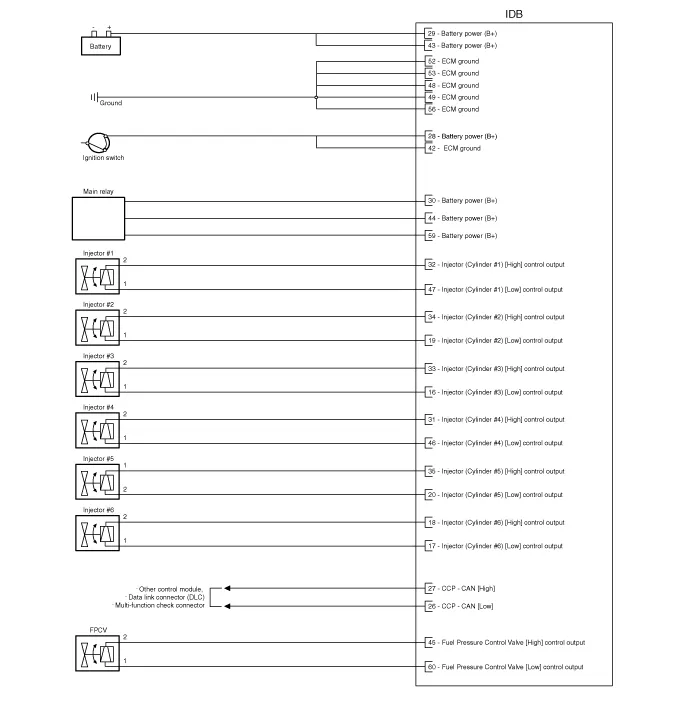

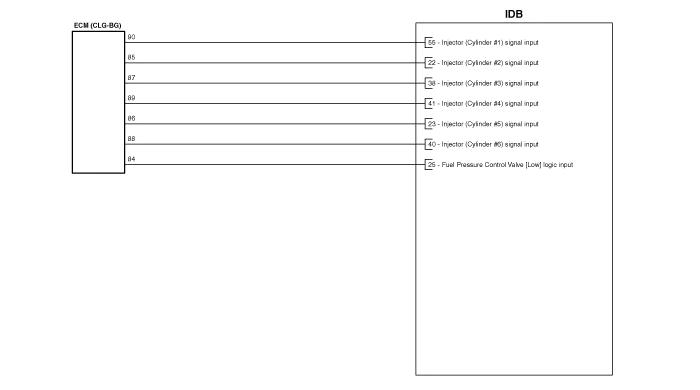

| Circuit Diagram |

Removal When replacing the ECM, the vehicle equipped with the immobilizer must be performed procedure as below. [In the case of installing used ECM] 1) Perform "ECM Neutral mode" procedure with GDS.

Removal 1. Turn the ignition switch off and disconnect the battery negative (-) cable. 2. Disconnect the injector drive box (IDB) connector (A).

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Surround View Monitoring Switch Repair procedures

Removal 1. Disconnect the negative (-) battery terminal. 2. Remove the floor console upper cover. (Refer to Body - "Floor Console Assembly") 3. Disconnect the console upper cover connector (A). 4. Remove the cup holder assembly (A) after loosening the mounting screws.

Kia Cadenza YG 2016-2021 Service Manual: General Safety Information and Caution

Instructions When Handling Refrigerant 1. R-134a liquid refrigerant is highly volatile. A drop on the skin of your hand could result in localized frostbite. When handling the refrigerant, be sure to wear gloves. 2. It is standard practice to wear goggles or glasses to protect your eyes, and gloves to protect your hands.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Transaxle Control Module (TCM) Repair procedures

- Driveshaft and axle

- Rail Pressure Sensor (RPS) Schematic Diagrams

- New on site

- Most important about car