Kia Cadenza YG: Tire Pressure Monitoring System / TPMS Sensor Repair procedures

| Removal |

| 1. |

Remove the tire. |

| 2. |

Remove the foreign substance from wheel. |

| 3. |

Discharge the air to the tire air inlet (A).

|

| 4. |

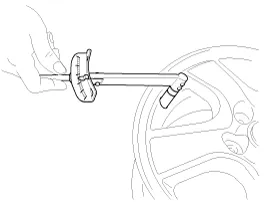

Install the bead brake from the tire and then remove the the tire rim by stepping slide bar, a pedal.

|

| 5. |

Carrying out the operation of the brake beads in various places until the fall tire completely from the rim. |

| 6. |

Put on the wheel turn table and then, fixed to the turntable wheel by stepping slide bar, a pedal. |

| 7. |

Install the rim of the wheel head mounting and then fixed.

|

| 8. |

Install the lever and then located to top tire between.

|

| 9. |

By stepping turntable pedal, rotated clockwise the turntable and then separate from the wheel outside the tire. |

| 10. |

Inside of the tire, it is to remove the tire from the wheel in the same way as No. 10.

|

| 11. |

Install in the reverse order of removal. |

| Installation |

|

| 1. |

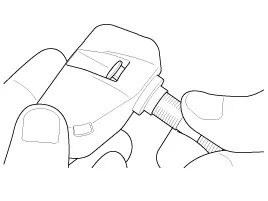

Assemble valve to sensor and turn valve 3 times with the square part of the screw in the slot.

|

| 2. |

Mount assembly to wheel.

|

| 3. |

Tighten washer and nut by hand until the valve thread meets the nut built-in calibrated stop.

|

| 4. |

Using a torque wrench, tighten the nut to 5.9±0.74 lb-ft

(8.0±1.0 Nm) It is normal to feel a break as the 1.7 lb-ft (2.3Nm)

calibrated stop in the nut snaps and the torque falls.

|

|

| Sensor ID Writing (Wireless) |

| Sensor ID Writing |

Description 1. Mode (1) Configuration State • All sensors should be in the Low Line state. • In High Line configuration, sensor transmissions occur every 1 minute (nominal) and pressure is measured every 4 seconds.

Description 1. Mode (1) Virgin State • The receiver as a sole part is shipped in this state. Replacement parts should therefore arrive in this state.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Antenna Coil Repair procedures

Removal 1. Disconnect the negative (-) battery terminal. 2. Remove the crash pad lower panel. (Refer to Body - "Crash Pad") 3. Disconnect the 6P connector (B) of the coil antenna and then remove the coil antenna (A) after loosening the screw.

Kia Cadenza YG 2016-2021 Service Manual: Specifications

Specification Air Conditioner ItemSpecificationCompressorType6VSX16Oil type & CapacityPAG OIL 100±10Pulley type6PK-TYPEDisplacement160cc/revCondenserHeat rejection14,400 ±5% kcal/hrA/C Pressure transducerThe method to measure the pressureVoltage= 0.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Specifications

- Schematic Diagrams

- Driveshaft and axle

- New on site

- Most important about car