Kia Cadenza YG: Driveshaft Assembly / Front Driveshaft Repair procedures

Kia Cadenza YG 2016-2021 Service Manual / Driveshaft and axle / Driveshaft Assembly / Front Driveshaft Repair procedures

| Replacement |

| 1. |

Loosen the wheel nuts slightly.

Raise the vehicle, and make sure it is securely supported. |

| 2. |

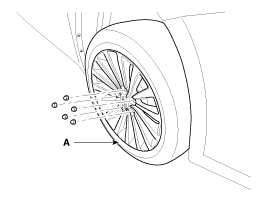

Remove the front wheel and tire (A) from front hub.

|

| 3. |

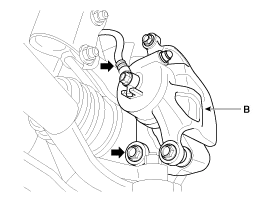

Remove the brake caliper mounting bolts , and then place the brake caliper assembly (B) with wire.

|

| 4. |

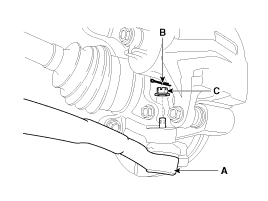

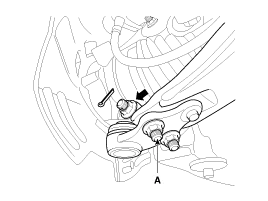

Remove the tie rod end ball joint (A) from the knuckle.

|

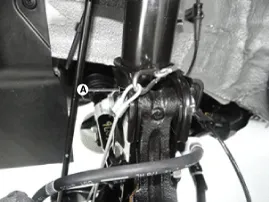

| 5. |

Loosen the mount bolt and then remove the wheel speed sensor (B) from knuckle (A).

|

| 6. |

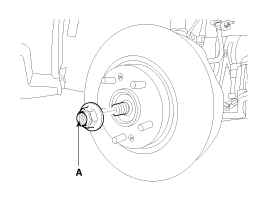

Remove driveshaft coking nut (A) from the front hub under applying the break.

|

| 7. |

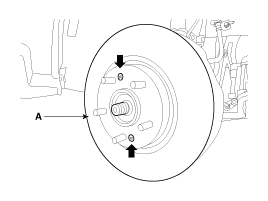

Loosen the front brake disc mount screw and then remove the front brake disc (A).

|

| 8. |

Remove the lower arm (A) from the knuckle.

|

| 9. |

Remove the front lower arm from the front knuckle using the SST (0K545-A9100).

|

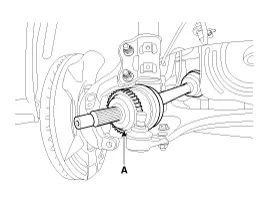

| 10. |

Disconnect the driveshaft (A) from the front hub assembly.

|

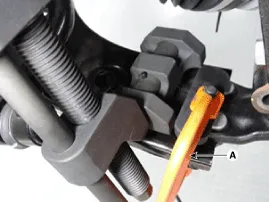

| 11. |

Remove the driveshaft cover (A).

|

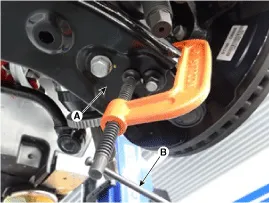

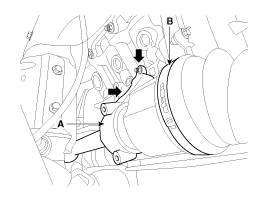

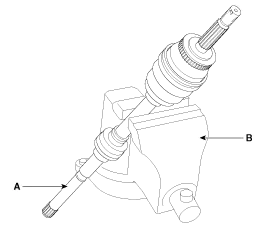

| 12. |

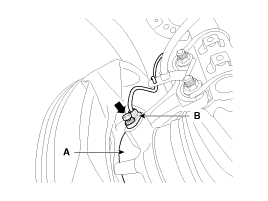

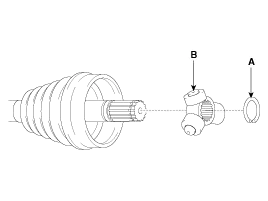

Loosen the mounting bolts and then remove the inner shaft (A) & driveshaft assembly (B).

|

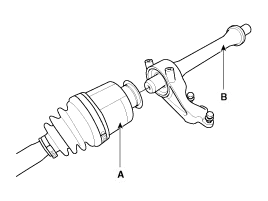

| 13. |

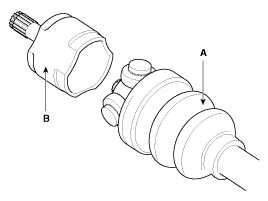

Disconnect the driveshaft (A) from inner shaft (B).

|

| 14. |

Install in the reverse order of removal.

|

| Inspection |

| 1. |

Check the driveshaft boots for damage and deterioration. |

| 2. |

Check the driveshaft spline for wear or damage. |

| 3. |

Check that there is no water or foreign material in the joint. |

| 4. |

Check the spider assembly for roller rotation, wear or corrosion. |

| 5. |

Check the groove inside the joint case for wear or corrosion. |

| 6. |

Check the dynamic damper for damage or cracks. |

| Disassembly |

|

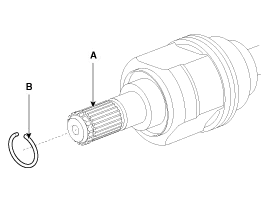

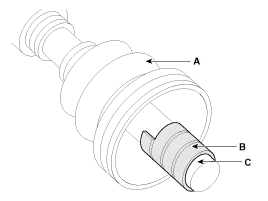

| 1. |

Remove the circlip (B) from the driveshaft spline (A).

|

| 2. |

Remove both boot bands from the transaxle side joint (UTJ) case.

|

| 3. |

Pull out the boot from transaxle side joint case (B). |

| 4. |

While dividing joint (UTJ) boot (A) of the transaxle side, wipe the grease in UTJ case (B) and collect them respectively.

|

| 5. |

Remove the snap ring (A) and spider roller assembly (B) from the shaft.

|

| 6. |

Clean the spider assembly. |

| 7. |

Remove the boot (A) of the transaxle side joint (UTJ).

|

| 8. |

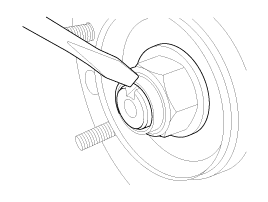

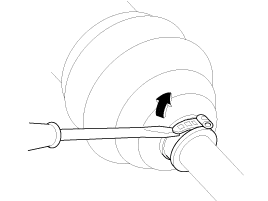

Using a pillar or flat-tipped (-) screwdriver, remove the both side of clamp (B) of the dynamic damper (A).

|

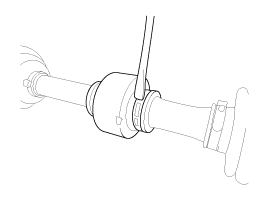

| 9. |

Fix the driveshaft (A) with a vice (B) as illustrated.

|

| 10. |

Apply soap powder on the shaft to prevent being damaged

between the shaft spline and the dynamic damper when the dynamic damper

is removed. |

| 11. |

Saperate the dynamic damper (A) from the shaft (B) carefully.

|

| Reassembly |

| 1. |

Wrap tape around the driveshaft spline (UTJ) to prevent damage to the boots. |

| 2. |

Apply grease to the joint boot on the side of the wheel and install the boot. |

| 3. |

Install the clamp. |

| 4. |

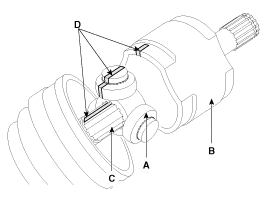

To install the dynamic damper (A), keep the shaft in a straight line and assemble the dynamic damper with the bands (B).

|

| 5. |

Assemble the transaxle side joint boot and bands. |

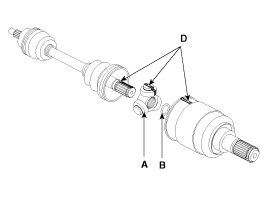

| 6. |

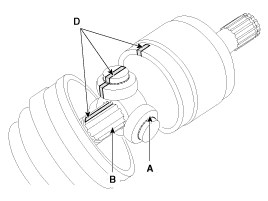

Using the alignment marks (D) made during disassembly as a

guide, install the spider assembly (A) and snap ring (B) on the

driveshaft splines (C).

|

| 7. |

Add specified grease to the joint boot as much as it was wiped away at inspection. |

| 8. |

Install the both boot band. |

| 9. |

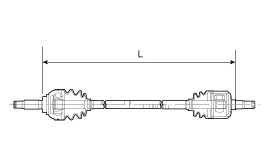

To control the air in the UTJ boot, keep the specified distance between the boot bands when they are tightened.

| ||||||||

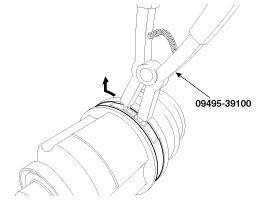

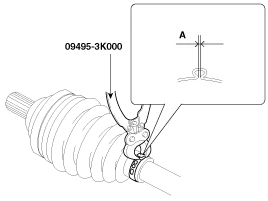

| 10. |

Using the SST (09495-3K000), secure the UTJ boot bands.

|

Component Location 1. Driveshaft(LH)2. Circlip3. Inner shaft bearing bracket assembly4. Circlip5. Driveshaft(RH)6. Components 1. BJ Assembly2.

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Blower Motor Repair procedures

Inspection 1. Connect the battery voltage and check the blower motor rotation. 2. If the blower motor voltage is not operated well, substitute with a known-good blower motor and check for proper operation. 3. If the problem is corrected, replace the blower motor.

Kia Cadenza YG 2016-2021 Service Manual: Heater & A/C Control Unit (DATC) Repair procedures

Inspection Self diagnosis 1. Self-diagnosis process 2. How to read self-diagnostic code. After the display panel flickers three times every 0.5 second, the corresponding fault code flickers on the setup temperature display panel every 0.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Body Electrical System

- Alternator Schematic Diagrams

- Battery Troubleshooting

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0203